In the engineering industry, digitizing old engineering diagrams is a significant

challenge, especially when scaling operations to manage millions of drawings.

Essential information such as the title, drawing number, revision number, and tags must

be extracted when digitizing engineering diagrams.

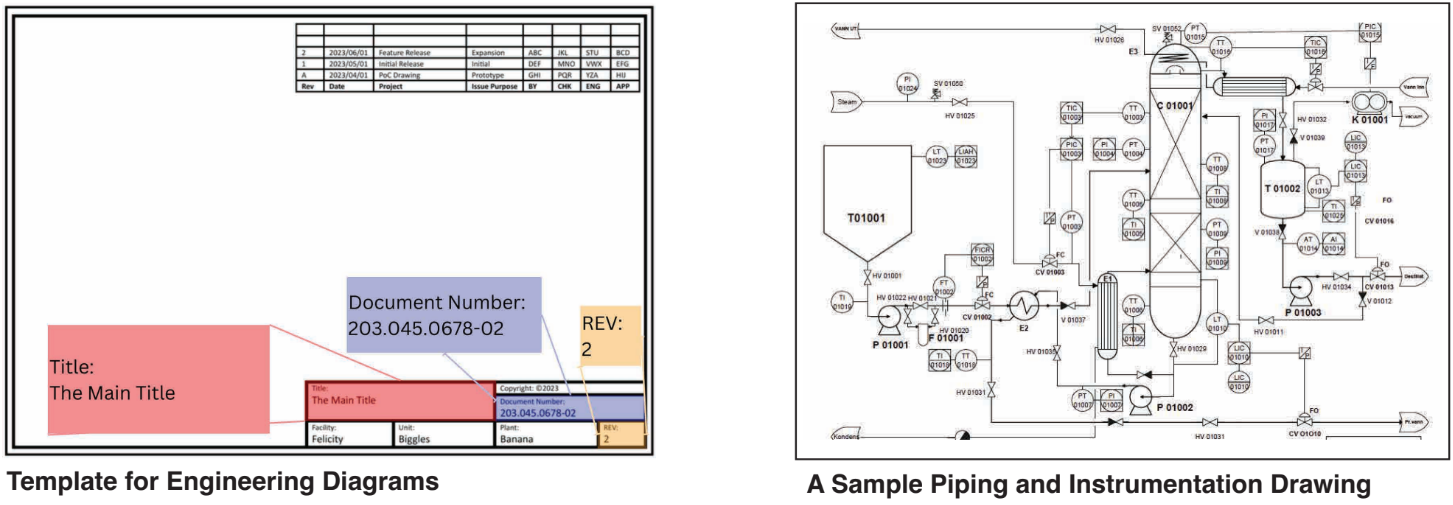

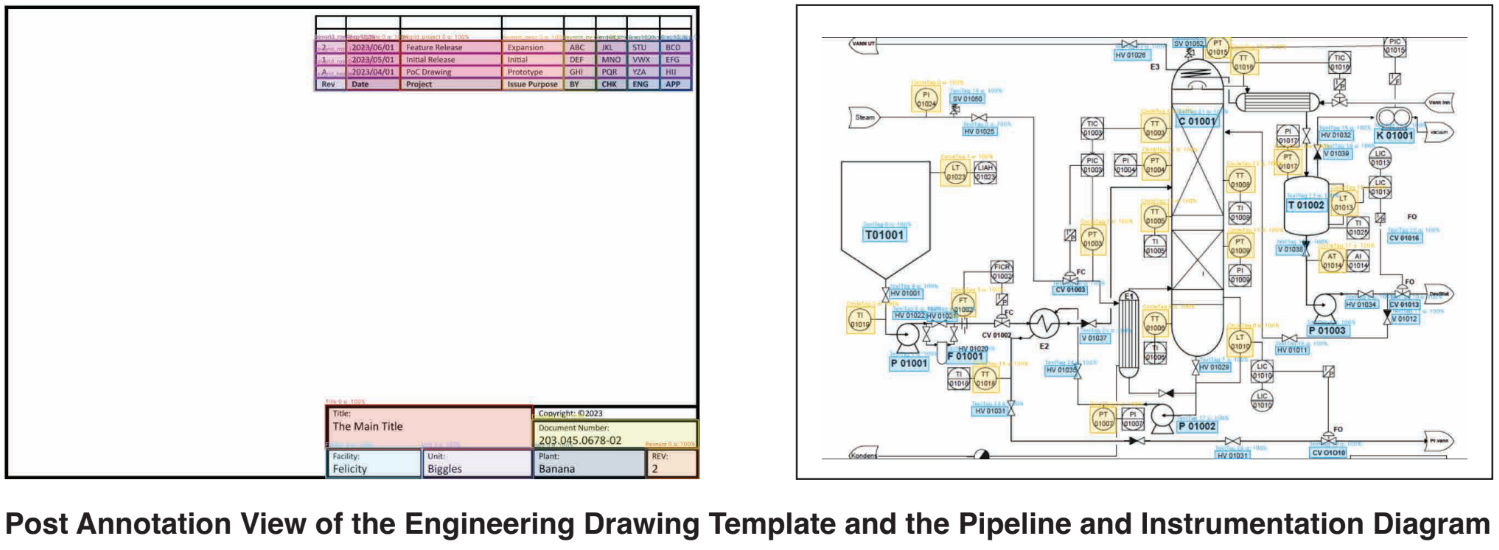

For example, in the diagram template below, the title, drawing number, and revision

number might be “The Main Title,” “203.045.0678-02,” and “2,” respectively. Despite

the apparent simplicity of this task, the global variety of templates, each potentially

containing thousands of diagrams, presents a formidable obstacle.

Furthermore, the existence of component tags in such drawings, as seen in the sample

Piping and Instrumentation Diagram, requires meticulous analysis, potentially straining

the eyes and constituting a heavy task for a single person, not the best use of their time.

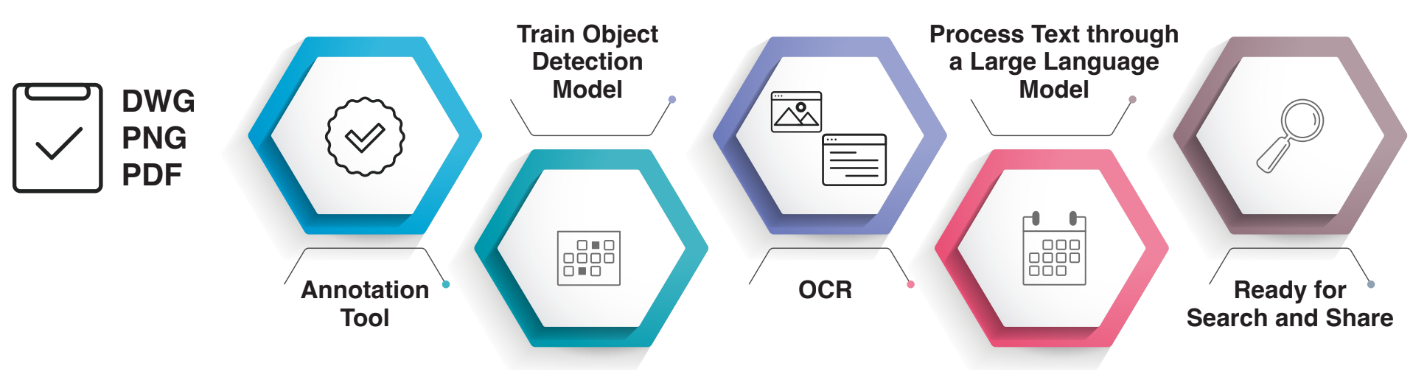

In such scenarios, rule-based software alone is insufficient to address this complexity.

Moreover, some drawings are handwritten, while others may be damaged by exposure

to sunlight or water. To effectively address these challenges, robust solutions are

required, as outlined in the subsequent section.